Commercializing Patterns & Colors

We have unparalleled know-how in commercializing often very complex designs across the full range of fabrics. We apply the strictest rigor from development to production and through to quality control to ensure that the vision meets the reality.

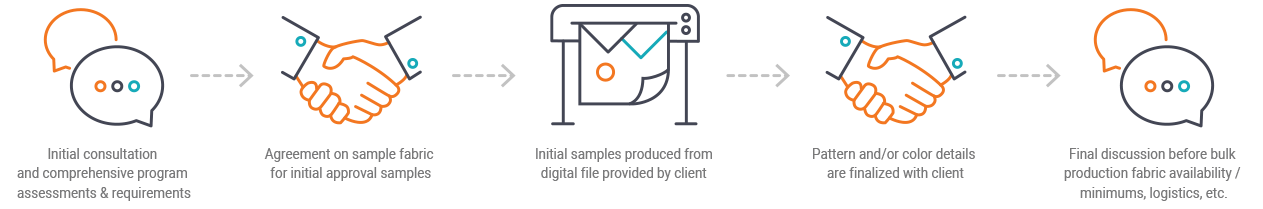

Pre-production Process

Production Process

Colormatch Process

Considerable time and effort go into the design and coloration of today’s patterns and it is entirely right that designers and brand owners are so particular about their commercialization onto printed fabric: their reputations rely on the appearance of their patterns. Printing the same pattern (with the same coloration) on different fabrics involves different factories, printing methods, dyestuffs and finishes. Furthermore, different finishes such as DWR, brushing and anti-microbials can also affect the final coloration of the fabric. With so many variables, it is perhaps understandable that most printing companies will tell you that it is impossible to achieve the same coloration on different types of fabrics, and unfortunately this attitude is quite evident in the marketplace.

In order to address this issue, our Colormatch process provides our customers consistent coloration for every pattern across a wide range of fabrics, meaning their products will merchandise better at retail. We have been involved in the printing of complex patterns on an extensive variety of fabrics for over 30 years, and our team has many years of experience in the global textile and textile processing business. Here are a few of the steps we take to achieve Colormatch:

-

Utilize only capable printers in strategic locations. In addition to having the right equipment, our printers possess the right culture and attitude. Complicated patterns require the printer to invest time and effort with us to color-match fabrics.

-

Too many printers today lack the personnel (good colorists and capable factory managers) to successfully achieve the right coloration on a complicated pattern. A printer can have modern equipment and state of the art technology, but if capable personnel are not on hand, achieving the right coloration will happen more by chance than design.

-

We have on staff colorists and factory-trained people highly experienced in all phases of the printing process. Our personnel actively participate and consult at the factory during the printing process to achieve the correct coloration. Developing Colormatch patterns on various substrates requires a considerable commitment by us. It is not unusual for several of our staff to take an entire working day at the printing factory (wherever it may be located) to achieve the right coloration. The results, however, speak for themselves both in terms of the appearance of the printed fabric and speeding up of the approval process.

-

Additionally, we take extensive steps to develop quality control procedures and establish various testing requirements for all the fabrics we produce.

-

Finally, we have an international supply chain team in place to handle the complexities of sampling, shipping, documentation, inspection, testing, and customer service.

A Stitch in Time (Problem Prevention)

Sourcing fabric involves many potentially costly pitfalls, and we have seen them all. The earlier we can become involved in your process – and help you to properly plan your supply arrangements – the better.

Fabric production is a surprisingly technical undertaking, involving considerations such as fiber content, yarn quality, weave, knit, etc. It must go through numerous mechanical and chemical processes to prepare it for each manufacturing step, as well as processes for printing, dyeing and many types of fabric finishing and treatments.

Through all of this, a finished fabric may be required to have strict limits on restricted substances and be tested for numerous regulatory compliances, as well as have stringent tolerances for shrinkage, colorfastness, uniformity, physical strength and many other characteristics.

It’s no wonder that quality issues can arise during a fabrics long journey to becoming a finished product, even when it seems you’ve done everything right. Often, these problems arise from overlooked requirements, incomplete communication and not enough attention to detail. These are nightmare scenarios for a manufacturer when discovered too late – with little recourse on ways to fix it. These setbacks can cost you time, money, orders and, worst of all, customers.

The good news is, with proper planning, specifications and manufacturing techniques, nearly all these situations can be avoided. If your current supplier is not providing satisfactory guidance in all three of these areas, reach out to our team of technical experts for a confidential discussion about your program. Schott Performance Fabrics offers comprehensive fabric solutions for almost any product, no matter how technically demanding it is. We thoroughly assess each program and take the time to understand your product and your expectations before executing the right plan to achieve your fabric goals.

E-mail us at hello@schottfabrics.com and let’s get started with a better solution.